0.35MW to 7 MW Industrial Hot Water Boiler

•CWNS series are horizontal internal combustion wet back shell boilers. Composed of a pot shell, a furnace, a back-combustion chamber, front and rear smoke boxes, fire tubes, etc.

•Small-scale adopts straight furnace, large-scale adopts corrugated furnace to strengthen heat transfer and improve thermal efficiency

•The back-combustion chamber adopts the butt welding process and the wet-back structure, which avoids the disadvantages of the welding seam easily falling off due to the back tube plate washed away by the high temperature flue gas, and ensures the safe operation of the boiler

• Delivered as a complete machine, touch screen, PLC program control, ordinary computer and other control systems are available

•The appearance is packaged in milky white color steel plate, which is beautiful and elegant

•Heating for hotels, residences, villas, office buildings and hot water for daily life and washing, heat preservation, disinfection, etc. in the catering industry

•Gym, gymnasium, swimming pool, rapid supply of large amounts of hot water;

• Heat supply for shopping malls and shopping centers;

•Heat source required for industrial washing, drying, and various heating;

•heating, washing, disinfection in hospitals and hot water places required for other industries

| Boiler Model |

CWNS1.05 |

CWNS1.2 |

CWNS1.4 |

CWNS1.75 |

CWNS2.1 |

CWNS2.45 |

CWNS2.8 |

CWNS3.5 |

CWNS4.2 |

CWNS5.6 |

CWNS7.0 |

| Rated calorific value(kcal/H) |

90 |

100 |

120 |

150 |

180 |

210 |

240 |

300 |

360 |

480 |

600 |

| Rated pressure(Mpa) |

0 |

| Outlet/inlet water temperature(℃) |

85/60 |

| Feed water temperature(℃) |

20/104 |

| Thermal efficiency(%) |

>92 |

| Boiler Stack Diameter |

400*280 420*300 520*310 500*280 650*300 680*300 680*300 680*360 700*320 700*350 850*400 |

| Nox emission(mg/m3) |

120/80/30 |

| Exhaust gas temperature(℃) |

60/150 |

| Fuel type |

Light diese1l oil/Heavy oil/Natural gas/Liquefied gas/City gas |

| Fuel consumption |

Light diese1l oil

(kg/h) |

96.1 |

112.2 |

133.2 |

165.5 |

195.5 |

190.8 |

264.2 |

330.5 |

384.1 |

516.9 |

667.5 |

Natural gas

(Nm3/h) |

115.6 |

134.4 |

156.8 |

193.5 |

234.0 |

228.7 |

317.2 |

388.5 |

463.1 |

620.1 |

775.7 |

| Max transportation weight(t) |

3.5 |

4.0 |

4.1 |

4.5 |

4.6 |

6.0 |

6.5 |

8.2 |

10.0 |

13.3 |

14.8 |

| Applicable Industries |

Manufacturing Plant, Food & Beverage Factory, textile/chemical/paper factory, etc |

| After Warranty Service |

Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location |

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan |

| Machinery Test Report |

Provided |

| Marketing Type |

New Product 2021 |

| Warranty of core components |

1 Year |

| Core Components |

boiler main part |

| Condition |

New |

| Type |

Natural Circulation |

| Usage |

Industrial |

| Structure |

Fire Tube/water tube /water-fire tube |

| Pressure |

no pressure |

| Steam Production |

Max 600kal/H |

| Style |

Horizontal |

| Fuel |

gas/oil/coal/biomass/wood.etc |

| Place of Origin |

Guangdong, China |

| Brand Name |

Dongguo |

| Output |

Hot water |

| Dimension(L*W*H) |

Depends on the boiler capacity |

| Weight |

3.5~14.8ton |

| Certification |

ISO, IAF,CE |

| Warranty |

1 Year, One Year warranty with full life service |

| After-sales Service Provided |

Engineers available to service machinery overseas |

| Key Selling Points |

High effiency and energy saving |

| Product name |

Dongguo 0.35MW to 7 MW Industrial Hot Water Boiler for sale |

| Color |

customization |

| Material |

Q345R Steel Plate |

| Capacity |

3.5 ton to 14.8 ton |

| Design pressure |

0 Mpa |

| Voltage |

220-460V/50-60Hz |

| Quality |

Strict producing and testing system |

| Installation |

Engineer abroad installation available |

How to get the best price quickly?

1. Please offer the boiler capacity & pressure you need, and the fuel you plan to use, then we could offer the suitable boiler model.

2. Please provide your name, email address, WhatsApp/WeChat/Skype, and company name, then we will send the best price and boiler details immediately.

What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some preparation for installation, and our experts will offer overseas installation service if you need, and fly to the installation site within 72 hours.

What is the using life of your boiler?

Normally the boiler is designed for 15 years life span, but with correct operation and well maintenance, the boiler operation life will be longer.

Boiler Maintenance Period

Inspect every 2~3 weeks, mainly checking valves, pipe, flanges, if any leackage, repair it timely. While every quater, make a whole inspection and repair.

Terms of Payment

T/T 30% of total contract value as down payment;

T/T or L/C 70% of total contract value before delivery.

If you have special requirements, we can take a special approach.

Advantages:

1.Reduce the installation work at site greatly and so reduce the possible abuse due to the poor skill of the installation stuff.

2.The combination of the modularization makes the unit is not affected by the stop of part.

3.The water in the furnace act as the heat media and doesn't take part in the exterior circulation, and tiny water replenishment make the warm boiler away from the end stack oxidizing at low temperature due to the low return water temperature. Thus prolong the life of the boiler.

4. The boiler produces heat at normal pressure and supplies heat under pressure. It is no need to perform the complicated boiler reporting and installation procedure. There is no limitation to the installation field.

5. Nanjing Runtech control technology is equipped with the unit; it is the advanced control technoiogy. The control system makes sure that your boiler runs safely.

Characteristics of the product

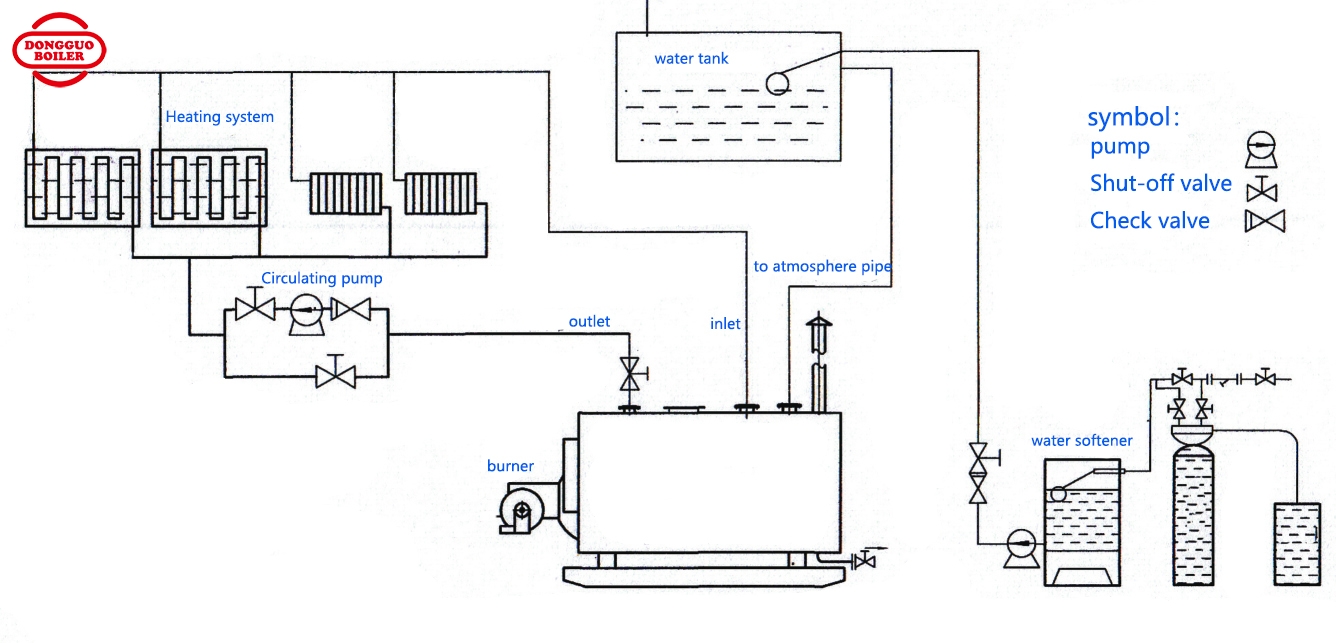

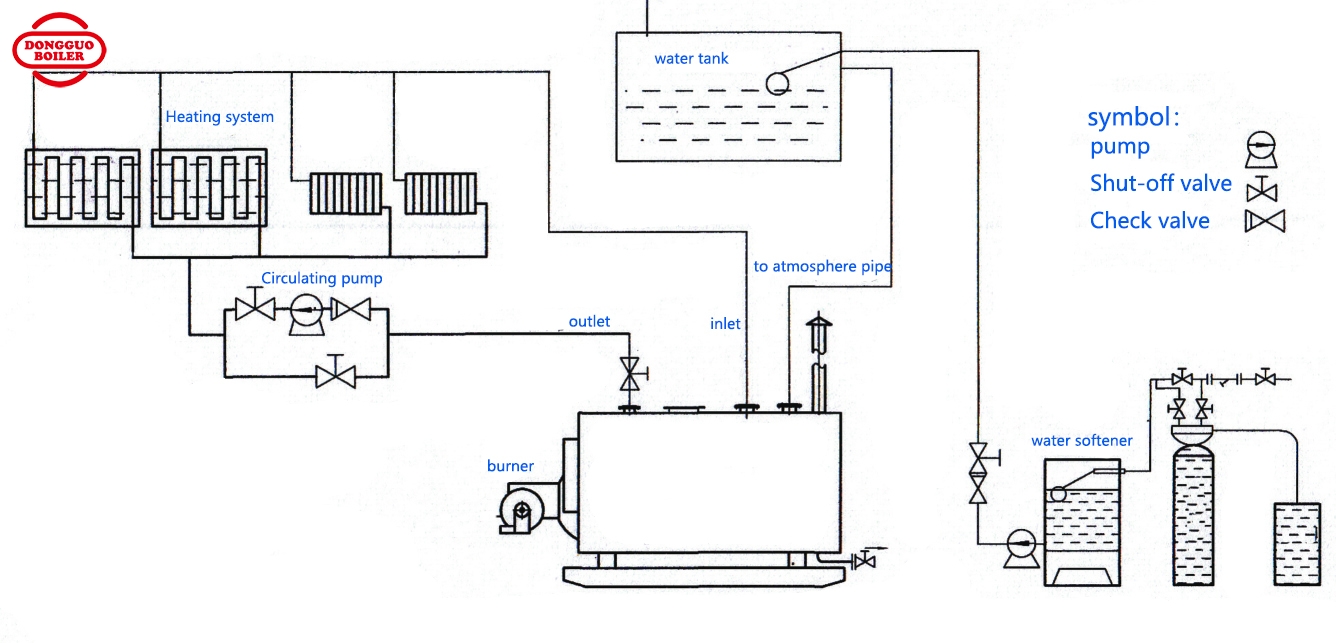

Center warm water unit (Heating indirectly)

Concept of the modularized: modularized center warm water unit is the unit that integrate the boiler, circulating pump, valves, instruments, control system and other parts and software in one modular, and all parts are assembled In the plant. The unit can be used in the field directly. Its function can be extended easily. The unit can meet the users' option at many aspects. Its advantage is very obvious.

Characteristic of structures:

Big hearth technology: the big volume radiation wave hearth make the combustion is completely. The heat efficiency is above 90%.

Flow Interrupts technology: to break the boundary of the mist laminar flow and strengthen the convection heat exchange.

Special design for the arrangement of the pipe makes the unit more compact. The high temperature mist enters into the two-travel mist tube from the back globe wet rear. The passage is designed influent, the resistance is low, and the noise of the running unit is low.

The elegant profile of the explosion proof door can be use as ash cleaning door.

Center warm water unit (heating directiy)

1. CWNS series is horizontal wet back internal-combustion shell type boiler. It is made up of the furnace shell, hearth, return combustion chamber, front! back mist box, fire tube etc.

2. Straight hearth is designed for the small boiler, and wave shape for big to intensify the heat transmission, thus to increase the heat efficiency.

3. The return combustion chamber is made with the butt welding process, and has a wet back structure, which avoid the disadvantage of the welding seam breaks off due to the back tube plate impacted by the high temperature mist.

4. The boiler is delivered integrate. Many control system such as touch screen; PLC programmed control and common computer eat. Can be chcsen by the customers.

5. Milk white color steel plate is used for the outer surface, which makes the boiler is beautiful and elegant.

Horizontal gas fired three pass atmospheric pressure hot water boiler